Harmful Effects of Dust on Laser Projectors

- BenQ

- 2019-07-17

With the progression of industrial development and increasing vehicular density in metro regions, air quality in major big cities around the world all suffer significant impact, particulate matter and ozone being the worst offenders. According to the latest study report published by the WHO, air pollution is now almost a global phenomenon, with the Middle East, North America and Southeast Asia standing out as the regions with the worst outdoor air pollution, air pollutants exceeding 5 times the guideline values defined by the WHO.

Dust will affect projection quality. Projectors with prolonged exposure to heavy dust and smog will have particulates gradually accumulate inside them, which leads to diminished performance on color and brightness, and might even speed up aging of optical components.

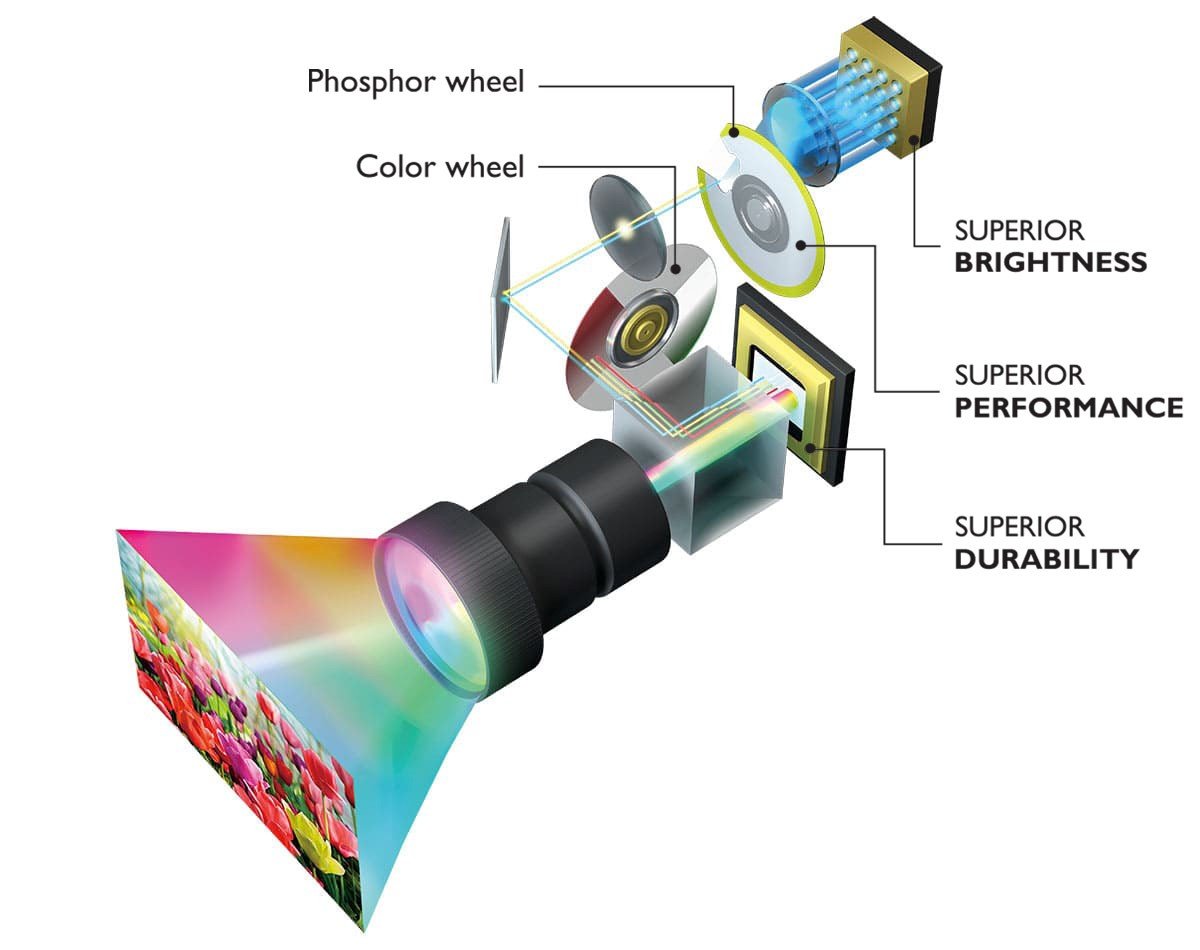

A laser optical engine is composed of many highly sophisticated optical components, with light source system and imaging system as its main systematic structure. The light source system mainly consists of: Laser Bank, Lens, Phosphor Wheel, Color Wheel, and UV/IR filter.

The imaging system mainly consists of: Rod, Prism, DMD (Chip), Projection Lens

Dust will affect projection quality. Projectors with prolonged exposure to heavy dust and smog will have particulates gradually accumulate inside them, which leads to diminished performance on color and brightness, and might even speed up aging of optical components.

The light source system of a laser optical engine is very sensitive to dust. During operation, zones with high electric field would attract dust particles, which might cause irreversible damage to the laser. This is especially true for high energy lasers, where dust particles might be burnt by the beam, and leave residue on the surface of filters and the color wheel. In some serious cases, after couple thousand hours, the brightness will reduce by half, and the saturation will decrease.

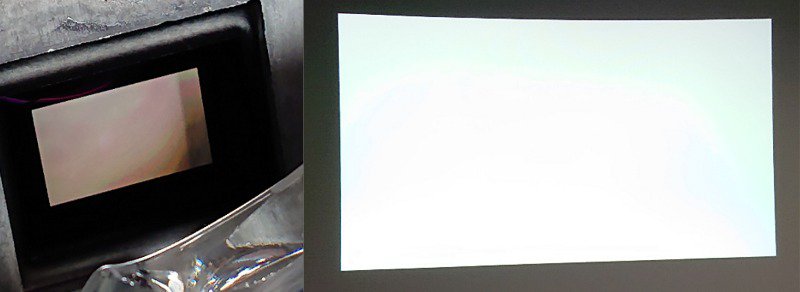

On the other hand, laser diodes might also be fried if dust latches onto them. The main function of the DMD chip in the imaging system of the optical engine is to process the high brightness and saturated colors from the light source system, generate and project images through the lens onto the screen. The cleanliness of the DMD chip's surface would affect projection quality, as seen in the figure below, the projection of a dusty DMD chip is littered with shady dots, while that of a clean DMD chip remain perfectly clear.

A dusty DMD chip's imaging surface leaves murky images, effecting projection quality

The projection of DMD chips that are not affected by dust

We found that aside from dust particles, cotton linters from our clothes and carbon black produced by vehicles or factories are also factors that might lead to early aging of the projector, therefore, our projectors come with BenQ's exclusive development verification for dust testing component, as proof that BenQ projectors are also suitable for outdoor use.

Cotton Linters -> 5%

Carbon Black -> 23%

Arizona Sand -> 72%

Acutely aware of air pollutions in the general environment, all of BenQ's laser optical engines comply with IP5X ingress protection ratings, certain models even reached a rating of IP6X; users would be able to enjoy a carefree, high quality projector experience.